Wafer Check Valve

Wafer Check Valve type combine a simple but robust construction with reliablity. They are specially developed for applications where a low pressure loss is essential. Opening and closing of the valve will take place at an extremely low pressure difference over the valve disc. The eccentric disc shaft connection. in combination with the disc seat guarantees positive shut-off of the returning medium.

- Body Type single Thin Plate, Short Type

- Suitable For Horizontal and Vertical Mounting

- Pressure Rating : PN-10/PN-16

- Seat Leakage : Zero Leakage, Tight Shut Off

- Temperature Range : 25°C to + 200°C

- Size Range: 1”to 42”

Product Description

TECHNICAL DATA

- MANUFACTURING STD. : BS 1868

- INSPECTION & TESTING STD.: API 6D / API 598

- END CONNCTION: WAFER TO SUIT ANSI B 16.5 150#/ DIN 2542(PN-10)/DIN 2543(PN-16)

| TEST PRESSURE | ||

| CLASS | HYDROSTATIC | |

| BODY | SEAT | |

| PN 10 | 10 Kg/cm2 | 6 Kg/cm2 |

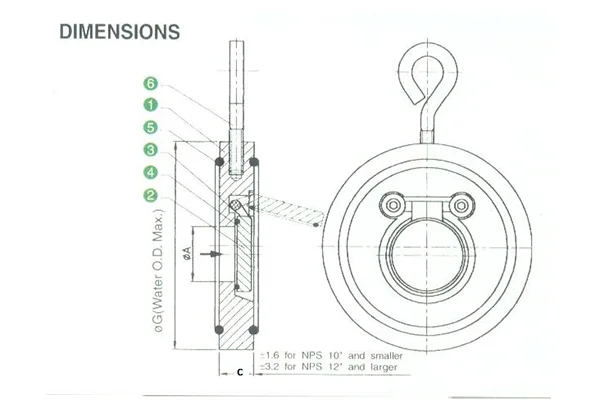

| Part | Nomenclature | Material | Qty |

| 1 | BODY | IS 210 FG. 200 / ASTM A 216 Gr. WCB ASTM A 351 CF8 / ASTM A 351 Gr. CF8M | 1 |

| 2 | CLAPPER | IS 210 FG. 200 / ASTM 216 Gr. WCB ASTM A 351 CF8 / ASRM A 351 Gr. CF8M | 1 |

| 3 | CLAPPER PIN | AISI 410 / AISI 304 / AISI 316 | 1 |

| 4 | CLAPPER SEAT | NIRTILE / EPDM / VITON / SILICON / PEFE | 1 |

| 5 | BODY SEAL | NIRTILE / EPDM / VITON / SILICON / PEFE | 1 |

| 6 | LIFTING EYE | M.S. / STAINLESS STEEL | 2 |

| 7 | NAME PLATE | ALLUMINIUM | 1 |

| SIZE | OA | OB | L |

| 50 | 30 | 109 | 19 |

| 65 | 40 | 129 | 19 |

| 80 | 52 | 144 | 19 |

| 100 | 71 | 164 | 19 |

| 125 | 93 | 194 | 19 |

| 150 | 114 | 220 | 19 |

| 200 | 157 | 275 | 28 |

| 250 | 195 | 330 | 28 |

| 300 | 230 | 380 | 38 |

| 350 | 270 | 440 | 41 |

| 400 | 310 | 491 | 51 |

| 450 | 360 | 541 | 51 |

| 500 | 406 | 596 | 60 |

| 600 | 490 | 698 | 70 |

| 1000 | 910 | 1200 | 180 |